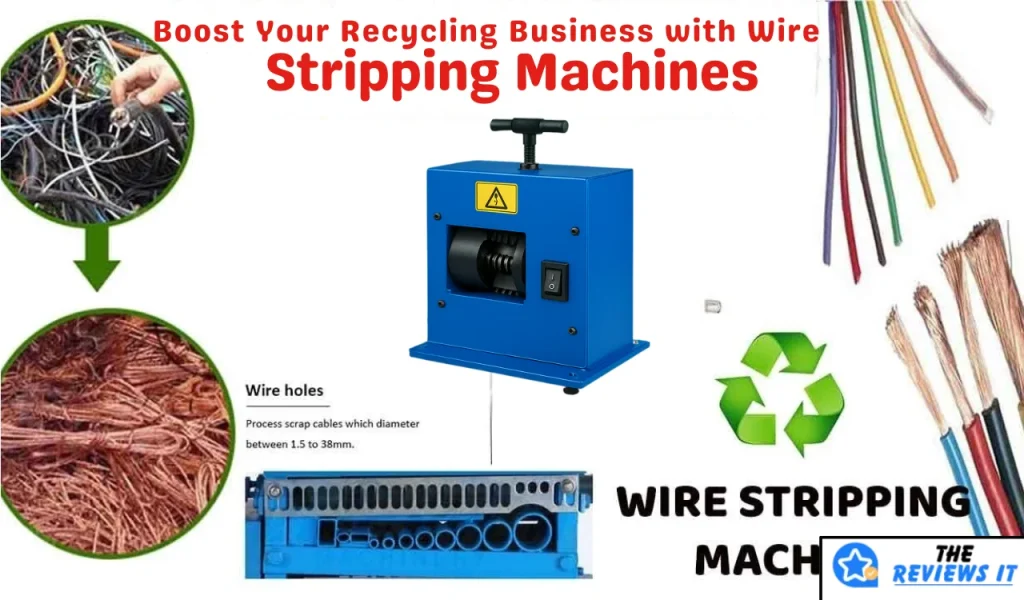

The recycling industry is booming, and with rising demand for raw materials, businesses are looking for smarter ways to increase efficiency and profits. One area that often goes overlooked is wire recycling. Beneath the plastic insulation of discarded cables lies one of the most valuable metals in circulation—copper. Extracting it properly can make a huge difference to your bottom line. That’s where wire stripping machines come in. These machines are designed to streamline the process, making it faster, safer, and more profitable for your recycling operation.

The Value Of Wire Stripping In Recycling

Wire stripping is the process of removing the plastic or rubber insulation from electrical wires to recover pure metal. For recycling businesses, this isn’t just a routine task—it’s a high-value opportunity. Copper and aluminum command strong resale prices, but their worth depends on purity. Clean, stripped metal fetches significantly more on the market compared to insulated wire. By investing in efficient wire stripping, you can reduce waste, increase your revenue, and strengthen your role in the circular economy.

Challenges Of Manual Wire Stripping

Some businesses still rely on manual methods, like using knives or hand tools, to strip wires. While this might work on a small scale, it creates several challenges:

- Labor-intensive and slow: Hand-stripping wires takes hours that could be spent on higher-value tasks.

- Inconsistent results: Improper stripping can damage the copper, lowering its resale value.

- Safety hazards: Sharp tools and repetitive motions increase the risk of injury.

These obstacles not only slow your operation but also cost you money in lost productivity and wasted material.

How Wire Stripping Machines Transform Recycling Businesses?

Wire stripping machines eliminate these issues by automating the process. Here’s how they can change the game for your recycling business:

- Speed and efficiency: Machines process large volumes of wire in a fraction of the time compared to manual labor.

- Precision: Adjustable blades and rollers ensure clean separation of insulation from copper or aluminum.

- Safety: Machines are built with safety guards and stable designs, reducing operator risk.

- Cost-effectiveness: By saving labor hours and increasing yield, these machines quickly pay for themselves.

For businesses handling high wire volumes, the productivity boost is immediate and significant.

Choosing The Right Wire Stripping Machine

Not all wire stripping machines are created equal. The right choice depends on the size of your operation and the type of wires you process.

- Wire size range: Check if the machine can handle the diameters you most frequently recycle.

- Motor power and speed: More power means faster processing, which is critical for large-scale operations.

- Adjustability: Machines with adjustable settings can handle a wider variety of wires.

Machine type:

- Manual models work for hobbyists or very small businesses.

- Electric or automatic machines are ideal for growing operations.

- Industrial models deliver maximum throughput for large recycling centers.

Taking time to match the right machine to your business scale ensures you maximize both efficiency and return on investment.

Business Benefits Beyond Scrap Value

The advantages of wire stripping machines extend far beyond the resale of stripped copper or aluminum.

- Higher throughput: Handle more material in less time, allowing you to scale operations.

- Worker productivity: Employees can focus on more valuable tasks instead of tedious hand-stripping.

- Safety improvements: Fewer accidents and reduced strain from repetitive work.

- Competitive advantage: By processing wire faster and cleaner, your business can outpace competitors.

- Environmental impact: More efficient recovery means less waste and greater contribution to sustainable recycling.

When viewed as a long-term investment, a wire stripping machine supports growth in nearly every area of your business.

Recommended Wire Stripping Machines For Businesses

If you’re ready to upgrade, consider reliable options like Creworks wire stripping machines. These machines are known for their durability, efficiency, and user-friendly design. With models ranging from compact electric strippers to heavy-duty industrial units, Creworks offers solutions that fit businesses of many sizes. Investing in a machine like this ensures you not only recover more copper but also save time, labor, and costs—directly boosting your bottom line.

Conclusion

Wire stripping machines are more than just tools—they’re growth drivers for recycling businesses. By improving efficiency, increasing safety, and maximizing the value of recovered metals, they can transform your operation into a more profitable and sustainable venture.